I-Palletizeriyimishini ezenzakalelayo esetshenziswa kabanzi emkhakheni wokukhiqiza ezimbonini, ikakhulukazi ezixhumanisini zokupakisha nezokuthutha. Isetshenziswa kakhulu ukupakisha ngobunono imikhiqizo ekhiqiziwe, efana nezikhwama, ezisebhokisini, nezinto ezisemathinini, kuma-pallets, skid, noma ezinye izithwali ngohlelo oluthile lokuhlelwa kanye nezendlalelo ukuze kwakheke umumo wesitaki ozinzile, ukuze kube lula imisebenzi elandelayo njengokugcina impahla, ukuthutha, ukulayisha nokuthulula.

Mayelana nesakhiwo kanye namamojula asebenzayo, ai-palletizerngokuvamile kuhlanganisa izingxenye ezibalulekile ezifana nesistimu yokudlulisa, idivayisi yokubamba nokubeka, isistimu yokulawula, nohlaka. Uhlelo lokudlulisa lunomthwalo wemfanelo wokudlulisa izinto ezizofakwa kuphalethi endaweni yokusebenza ye-palletizer ngendlela ehlelekile, iqinisekise ukuthi izinto zingafinyelela ngokunembile endaweni ebekiwe futhi zilungiselele imisebenzi yokubamba elandelayo. Idivaysi yokubamba nokubeka iyisici esiyinhloko se-palletizer. Ingasebenzisa izindlela ezihlukene zokubamba, njengezibambi zemishini, izinkomishi zokumunca i-vacuum, izindlela zokubopha, njll., ngokuya ngokuma, usayizi nesisindo sezinto ezihlukene, ukuze ibambe kahle izinto futhi izibeke ngokushelela ezindaweni ezihambisanayo ngokuya ngemodi yokupakisha esethiwe, ukuze ibone ukupakishwa okuhlelekile kwezinto. Uhlelo lokulawula "ubuchopho" be-palletizer. Ilawula ngokunembile yonke inqubo ye-palletizing ngezinhlelo ezakhelwe ngaphakathi nama-algorithms, okuhlanganisa isivinini sokusebenza sohlelo lokudlulisa, ukulandelana kwesenzo kwedivayisi yokubamba, indawo kanye nezendlalelo zokupakisha, njll., ukuze kuqinisekiswe ukuzenzela nokusebenza kahle kwenqubo yokuhlanganisa. Uhlaka luhlinzeka ngesakhiwo sokusekela esizinzile sengxenye ngayinye ye-palletizer, iqinisekisa ukuzinza nokuthembeka kwemishini ngesikhathi sokusebenza.

Ngokuhamba komsebenzi, lapho izinto ezizofakwa i-palletizer zingena ebangeni lokusebenza le-palletizer ngohlelo lokudlulisa, isistimu yokulawula izothumela imiyalelo kudivayisi yokubamba nokubeka ngokuvumelana nemingcele ehleliwe kanye nesimo samanje sokusebenza. Idivayisi yokubamba isebenza ngokushesha, ibamba izinto ngokunembile, bese ihambisa izinto endaweni ebekiwe ngaphezu kwephalethi ngokwendlela yokupakisha ehleliwe bese izibeka phansi kancane ukuze kuqedelwe ukupakisha ungqimba olulodwa lwezinto. Ngemva kwalokho, isistimu yokudlulisa iyaqhubeka nokudlulisa iqoqo elilandelayo lezinto, futhi idivayisi yokubamba iphinda izenzo ezingenhla ukuze sistake isendlalelo esilandelayo. Lo mjikelezo uqhubeka kuze kube yilapho i-pallet inqwabelene enanini elimisiwe lezendlalelo ukuze kwakhe isitaki esiphelele. I-pallet eqedile ukupakisha izothuthwa isuke endaweni yokusebenza ye-palletizer ngesistimu yokudlulisa bese ingena endaweni yokugcina impahla noma isixhumanisi sokuthutha.

Ama-Palletizerszinezinzuzo eziningi ezibalulekile. Okokuqala ukusebenza kahle. Ingakwazi ngokuqhubekayo ukwenza imisebenzi ye-palletizing ngesivinini esisheshayo, esithuthukisa kakhulu ukusebenza kahle kokukhiqiza uma kuqhathaniswa ne-palletizing eyenziwa ngesandla futhi ingahlangabezana nezidingo zokusebenza ezisebenzayo zamabhizinisi amakhulu okukhiqiza. Okwesibili ukunemba. Ngohlelo olunembile lokulawula kanye nesakhiwo somshini, i-palletizer ingaqinisekisa ukuthi into ngayinye ibekwe ngokunembile endaweni enqunywe kusengaphambili, futhi umumo ohlanganisiwe uhlanzekile futhi uzinzile, ugwema izinkinga ezifana nokungahambi kahle nokuthambekela okungenzeka ku-palletizing manual, okuhambisana nokuphepha kokugcinwa kwempahla nokuthutha. Okwesithathu ukuzinza. I-palletizer ingasebenza ngokuzinza isikhathi eside futhi ayithinteki kalula yizici ezifana nokukhathala kwabasebenzi nemizwelo, engaqinisekisa ukuqhubeka nokuzinza kwenqubo yokukhiqiza futhi ithuthukise izinga lokuphatha ukukhiqiza lamabhizinisi. Ngaphezu kwalokho, mayelana nokuqina kwabasebenzi kanye nezindleko, ukusetshenziswa kwama-palletizer kunciphisa kakhulu amandla okusebenza kwabasebenzi futhi kunciphisa ukuthembela kwamabhizinisi emsebenzini. Ikakhulukazi kwezinye izimo ze-palletizing ezinomfutho wemisebenzi ephezulu kanye nezindawo zokusebenza ezinokhahlo (ezifana nezinga lokushisa eliphezulu, izinga lokushisa eliphansi, uthuli, umsindo, njll.), akuqinisekisi impilo yabasebenzi kuphela kodwa futhi kunganciphisa izindleko zabasebenzi ngokwezinga elithile.

Ngokuthuthuka okuqhubekayo kobuchwepheshe bezimboni ezishintshayo, ama-palletizer abuye athuthukiswe ngokuqhubekayo futhi aphindwe. Ama-palletizer esimanje aya ngokuya ehlanganisa ubuchwepheshe obuthuthukile njengobuhlakani bokwenziwa kanye nokubona komshini. Ukusetshenziswa kobuchwepheshe bokubona komshini kwenza ama-palletizer abone ukuma, umbala, indawo kanye nolunye ulwazi lwezinto ngesikhathi sangempela ngokusebenzisa izinzwa ezibukwayo ezifana namakhamera, ngokuqhubekayo ukuthuthukisa ukunemba nokubamba nokubeka. Ngisho noma kukhona ukuchezuka kwendawo yezinto phakathi nenqubo yokudlulisa, kungalungiswa ngokuzenzakalelayo futhi kunxeshezelwe. Ubuchwepheshe bobuhlakani bokwenziwa bungenza ama-palletizers abe nekhono elithile lokufunda nokwenza kahle, alungise ngokuzenzakalelayo isu lokunqwabelanisa ngokwemisebenzi ehlukene yokukhiqiza nezici zento, futhi abone ukusebenza kwe-palletizing okuhlakaniphe kakhulu nokusebenza kahle.

Ngamafuphi, njengenye yemishini ebalulekile ye-automation yezimboni, ama-palletizer adlala indima engenakushintshwa ekukhiqizweni kwezimboni zesimanje. Azithuthukisi nje kuphela ukusebenza kahle kokukhiqiza kanye nekhwalithi yomkhiqizo wamabhizinisi kodwa futhi zikhuthaza ukuzenzela kanye nokuthuthukiswa okukhaliphile kwayo yonke inqubo yokukhiqiza, ukuhlinzeka ngosekelo oluqinile lokunciphisa izindleko zamabhizinisi, ukukhuphula ukusebenza kahle kanye nentuthuko esimeme.

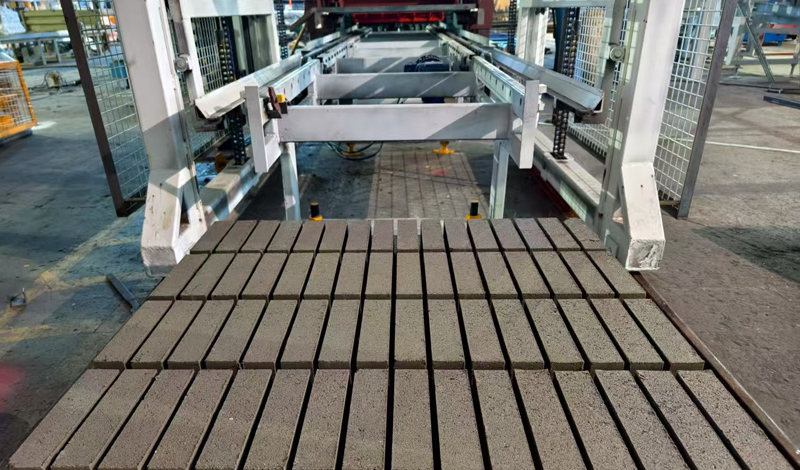

Umshini osesithombeni u-ai-palletizer.

I-palletizer iyisisetshenziswa esibalulekile esizenzakalelayo ekukhiqizweni kwezimboni, ikakhulukazi emikhakheni yokupakisha kanye nempahla. Isetshenziswa kakhulu ukupakisha ngobunono imikhiqizo ehlukahlukene efana nezikhwama, efakwe emabhokisini, kanye neyasemathinini ezithwalini ezifana namaphalethi ngendlela ethile kanye nezendlalelo ukuze kwakheke umumo wesitaki ozinzile, kube lula ukugcinwa kwempahla, ukuthutha, ukulayishwa kanye nokuthulula.

Mayelana nesakhiwo, i-palletizer iqukethe izingxenye ezifana nesistimu yokudlulisa, idivayisi yokubamba nokubeka, isistimu yokulawula, kanye nohlaka. Uhlelo lokudlulisa ngokuhlelekile luthumela izinto ukuze zifakwe i-pallet endaweni yokusebenza; umshini wokubamba nokubeka uwumgogodla, okwazi ukubamba ngokunembile izinto ngokubamba imishini, izinkomishi zokumunca i-vacuum, njll. ngokuvumelana nokuma kwezinto bese uzibeka ngendlela esethiwe ngayo; isistimu yokulawula, “njengengqondo”, ilawula ngokunembile isivinini sokudlulisa, ukulandelana kokubamba, indawo yokupakisha kanye nezendlalelo ngokusebenzisa ama-algorithms wohlelo ukuze kuqinisekiswe ukuzenzekelayo nokusebenza kahle; ifreyimu inikeza ukusekelwa okuzinzile kwengxenye ngayinye.

Ngesikhathi sokusebenza, izinto ezizofakwa kuphalethi zingena ebangeni lokusebenza ngohlelo lokudlulisa, futhi isistimu yokulawula ithumela iziyalezo ocingweni lokubamba nokubeka ngokuya ngemingcele nesimo. Idivayisi yokubamba ibamba ngokushesha izinto, izihambise endleleni ehleliwe iye endaweni eqokiwe ngaphezu kwephalethi bese izibeka phansi kancane ukuze iqedele ukunqwabelanisa ungqimba olulodwa. Ngemva kwalokho, isistimu yokudlulisa ithumela iqoqo elilandelayo lezinto, futhi idivayisi yokubamba iphinda isenzo sokupakisha isendlalelo esilandelayo. Umjikelezo uyaqhubeka kuze kube yilapho i-pallet ifinyelela inombolo emisiwe yezendlalelo ukuze yenze isitaki esiphelele, bese ihanjiswa ngesistimu yokudlulisa ukuze ingene endaweni yokugcina impahla noma isixhumanisi sokuthutha.

Ama-Palletizerszinezinzuzo ezibalulekile, ukusebenza kahle, ukunemba nokuzinza. Banganciphisa amandla okusebenza kwabasebenzi kanye nezindleko zabasebenzi bamabhizinisi, futhi baqinisekise ukusebenza ezindaweni ezinokhahlo. Ngokuthuthukiswa kwe-automation yezimboni, baphinde bahlanganise ubuchwepheshe obufana nobuhlakani bokwenziwa kanye nombono womshini ukuze kuthuthukiswe ukunemba nokuhlakanipha, ukusiza amabhizinisi ukunciphisa izindleko, ukwandisa ukusebenza kahle kanye nokuzuza intuthuko esimeme.

Isikhathi sokuthumela: Sep-05-2025

+86-13599204288

+86-13599204288